EradiFluor: PFAS destruction using energy-saving technology

You need a way to destroy PFAS, not just concentrate or transfer them.

Enter EradiFluorTM, Haley & Aldrich’s efficient, cost-effective PFAS-destruction technology.

Why EradiFluor?

Efficient PFAS destruction with no harmful byproducts

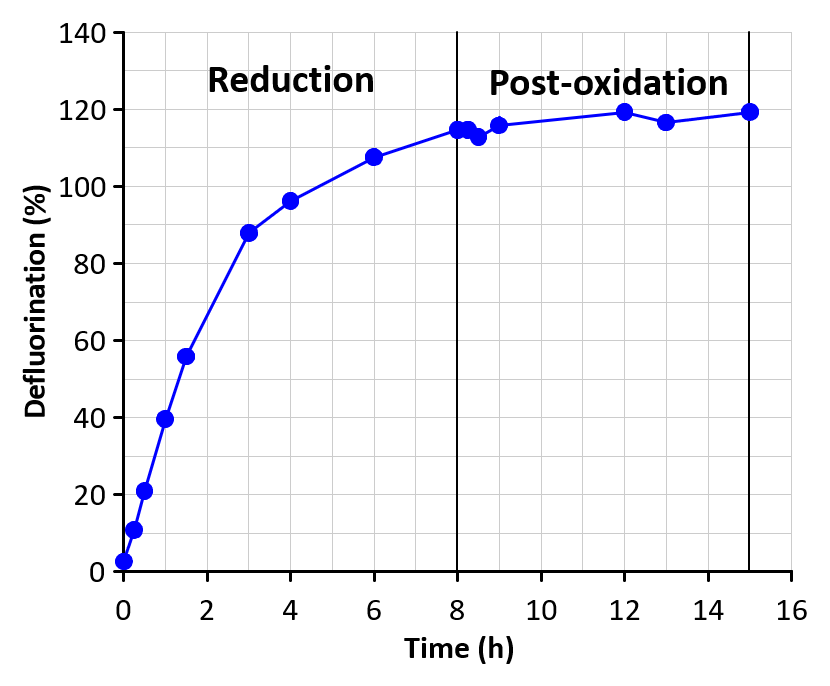

EradiFluor has shown a defluorination rate of almost 100 percent, exceeding that of many other technologies.

And other technologies simply concentrate or transfer PFAS, also known as per- and polyfluoroalkyl substances, meaning the substances still need to be disposed of.

EradiFluor destroys PFAS in concentrated waste with no harmful byproducts (e.g., perchlorate and bromate) that would require more expensive treatment.

Lower energy use

EradiFluor relies on ultraviolet (UV) light and common chemicals to destroy PFAS. This process uses less energy than other technologies — saving money and supporting sustainability goals.

Safer to operate

The technology operates under ambient pressure and in temperatures lower than 60 degrees Celsius, unlike the many alternative destructive technologies that require high temperature and high pressure — and hence special health and safety measures — to operate.

Flexible, scalable implementation

Customers can ship waste to a central location or build as many small-footprint units as needed on site.

Backed by highly competitive funding

We developed this technology with financial support from the Department of Defense’s Environmental Security Technology Certification Program and the Air Force Civil Engineering Center, which require rigorous peer review and vetting.

Who needs EradiFluor?

Industrial and manufacturing facilities

Treat concentrated waste from any operations.

Landfills

Destroy PFAS-rich leachate.

Water treatment plants

Tackle PFAS in drinking water, wastewater, and concentrated waste.

How does EradiFluor work?

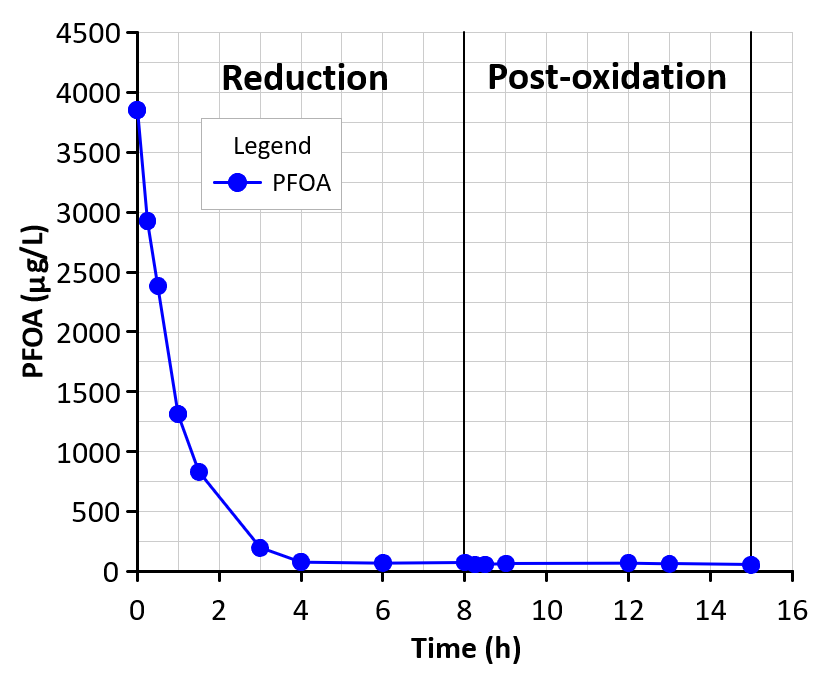

It processes liquid waste containing high concentrations of PFAS through one or two treatment loops, depending on the compounds involved and the level of contamination. UV light reacts with sulfite under elevated pH to produce highly reactive hydrated electrons that break down carbon-fluorine bonds in PFAS. Depending on waste sample properties, optional pretreatment and posttreatment steps using an advanced oxidation process can be added to improve the treatment’s efficiency. Users can send the effluent from EradiFluor to the influent of a separation treatment process for further concentration or discharge following a polishing treatment step.

EradiFluor can target:

- Ion exchange resin regeneration brine.

- Activated carbon regeneration residue.

- Membrane filtration rejectate.

- Foam fractionate.

- Unused aqueous film-forming foam (AFFF).

- AFFF rinsate residue.

- Residue from soil washing.

- Other concentrated PFAS waste.

We measured how well EradiFluor degraded perfluorooctanoic acid (PFOA), a common PFAS found in consumer products, food packaging, fire-fighting foam, and industrial processes. We achieved 99% PFOA degradation and nearly 100% defluorination based on fluorine mass balance and target PFAS analysis, or near-complete removal and destruction of PFOA.

Let’s connect